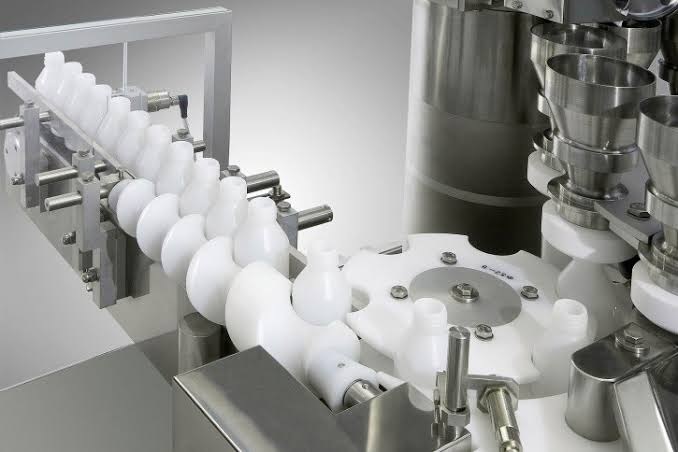

Due to globalization, the number of industries is increasing at an exponential rate. The production sector doesn’t seem to stop growing, thanks to rising demand. To tap the potency of growth, many manufacturers invest in the production sector. If you’re one such businessman, consider using manufacturer timing screws systems in your factory. Although other options exist, these systems are much better than their counterparts. Let’s find out more about timing screw systems to arrive at an informed decision.

Benefits of using manufacturer timing screws systems

Most newbie businesses are skeptical about using an innovative technique. They fear that the modern process may not align with their needs. Perhaps, the technique is too costly or involves substantial risks. All such worries keep business owners from choosing a new system. However, timing screw systems come with no drawbacks. Rather, they provide a slew of advantages.

Space-efficient

Modern sheds and factories are pressed for space. Manufacturers have to carry out their processes within the available space. What if you want to increase the production capacity? You may have to buy or rent another factory. That can increase your investment budget substantially.

A timing screw system comes in handy to save space. These systems warrant minimal space for operations. You can double or triple your production capacity without adding a new shed. The reason – timing screw systems occupy limited space. You can mount a few such systems and increase your production to match the increasing demand.

Safety

Any manufacturing system poses the risk of injuries. No matter how careful you’re, accidents happen. A single accident can impair the worker and keep him from his day to day activities. Not just that, you may have to pay the injured worker a big sum, and that can impact your finances.

A timing screw system overcomes this issue. These systems come with enhanced safety measures. In the case of any unfortunate event, the machine stops running, thus averting injuries. As well as preventing accidents, these systems save enough money that could have been otherwise paid to the injured worker.

Speed

The modern world thrives on speed. As a manufacturer, you ought to increase your production speed to supply goods on time. If you fail at this point, your clients will move onto other suppliers. Timing screw systems are speedy.

They increase your production and reduce wastage. In this way, the overall cost gets reduced. Plus, increased production leads to economies of large scale production and competitive pricing. In the end, you can price your product efficiently in the market, paving the path for higher sales and better profitability.

Cost-effective

Most businesses think that investing in timing screws manufacturer systems might be an expensive affair. However, this isn’t the case. A substantial number of machine vendors sell these systems at a budget price. Plus, the systems are available in varied price ranges. You may choose the model that best suits your budget. In the end, you get a system that aligns with your needs on a budget.